WORKSHOP BRAND PROCESS

A detailed outline of the procedure taken by Morgan-Lee Lewis to complete styles for Workshop Brand:

Morgan first works closely with the Designers of Workshop Brand and assists in the designing process. After the initial design meeting Morgan is responsible for sourcing the soft and hard goods required to complete the first sample. A preliminary costing is done with potential soft and hard goods needed along with potential yield per garment amounts and any other expenses associated with this style.

The reference garment along with a tech pack and design spec created by Morgan, are provided to a local Pattern Maker for first pattern and sample marker creation. Then the first sample marker, tech pack, and reference sample are taken to a local production facility along with all goods required (BOM) to construct the first sample. During the sampling stage Morgan meets with the Facility Manager to discuss and coordinates the construction of the first sample and any issues that may come up. All feedback from the sewers and cutters are taken and compiled to discuss with designers and pattern maker upon first sample review.

The first sample is taken for a design and fit meeting. The Designers and Morgan meet and discuss the finished 1st sample. All changes are recorded on the garment and on paper and are compiled into another tech pack and revisions spec sheet. This along with the first sample and reference garment are taken to the pattern maker for revisions and if needed an additional sample marker will be created. Then (if required) an additional sample is sewn at the same facility as the first sample and another fit session is conducted for the 2nd sample. This continues until a final sample that meets all requirements from the Designers and Brand Manager, Morgan is finished.

Once a final perfectly fitting sample and sample pattern are complete the pattern is graded and a production marker is requested by Morgan from the Pattern Maker. During the sampling stage Morgan is sourcing and placing PO for all soft and hard goods that are required for the style. These are ordered so their delivery lines up 5-7 business days before production is to start.

Once all goods, production marker, tech pack and final sample are ready, production is started by Morgan at the facility. Production and any issues that may come up are managed by Morgan. Final costing is completed and provided to designers once the finished goods are received in house and quality control measures are taken.

Once final product is reviewed by the designers and SRP's are assigned, Morgan completes the final Information Package for the receiving department at head office. This includes all size, colour and pricing info needed to get the product tagged and sent to the stores.

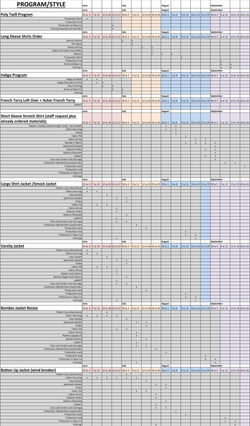

All steps of the Workshop Brand Process are recorded and managed through a Production Calendar (see below for example) by Morgan.

Along with the above description Morgan is also heavily involved in the online marketing of the brand (including Facebook, Twitter, Instagram and brand website), label and hangtag design and creation, as well as retail feedback coordination. Morgan has also attended many sourcing trade shows in order to find new and valuable suppliers. Shows such as MAGIC in Las Vegas, The DG Expo in San Francisco, and the LA Textile Show in Los Angeles.

|  |

|---|---|

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|